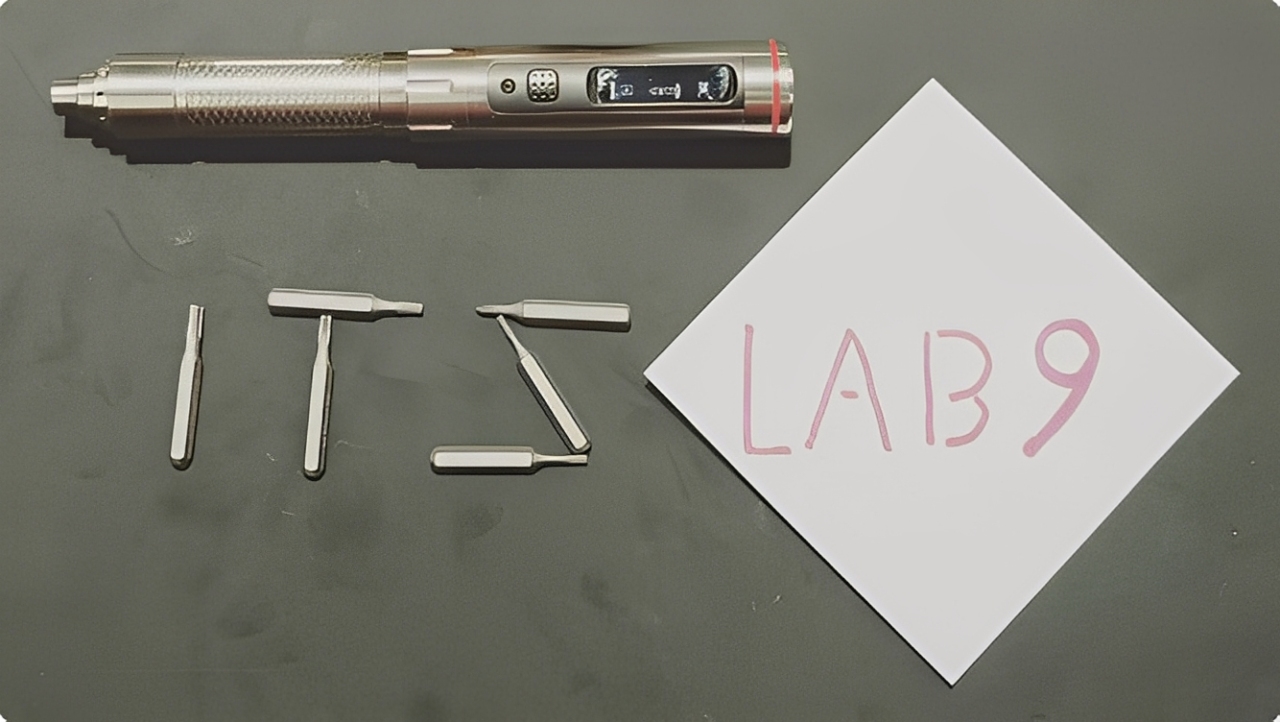

ABOUT IT'SLAB9

Where Design, Precision, and Imagination Converge

Lab9 Engineering is a full-scale research, design, and manufacturing laboratory — created by Ishan Thakore, a mechanical engineer with deep expertise in 3D printing, piezo systems, binder jet technology, electronics, and material process design.

At Lab9, engineering isn’t theoretical. It’s physical, tactile, and alive. Every part, machine, and mechanism inside this facility has been designed, prototyped, or re-engineered in-house to serve one purpose.

What We Do

Precision 3D Printing Services

Lab9 specializes in functional 3D printing for industrial applications — not just prototypes, but parts meant to live and perform.

We offer:

- Industrial 3D printing in sand, metal, and polymer

- Binder jet R&D and process development

- Per-layer compaction and vacuum-assisted build systems

- Custom material validation for casting, tooling, and performance

Every component printed at Lab9 is part of a real engineering challenge — fixtures, housings, mechanisms, and precision test models built for industrial results.

→Design & CAD Services (Per Hour)

Lab9 provides professional CAD, simulation, and mechanical design services on a per-hour basis.

This service is ideal for:

- Industrial R&D teams needing rapid mechanical design

- Startups requiring low-cost prototype validation

- Machine builders needing precision fixture or head design

- Automation engineers integrating motion and print systems

Our design philosophy is centered on manufacturability — ensuring every design moves smoothly from CAD → CNC or additive manufacturing with no compromise.

→

THE ENGINEER BEHIND IT

ISHAN THAKORE

Mechanical Engineer | Additive Manufacturing Specialist | Systems Designer

Ishan’s experience spans additive manufacturing systems, printhead design, material science, and embedded controls. His career has revolved around building machines that blend mechanical perfection with electrical intelligence — from multi-printhead textile printers to sand binder jetting prototypes capable of micron-level accuracy.

He’s a problem solver, system integrator, and relentless perfectionist — the kind of engineer who dissects machines to build better ones.

Lab9 is his creation — a facility designed, wired, and fabricated by hand, where every 3D-printed bracket, fixture, and layout choice exists to optimize work efficiency and precision.

Engineering Approach

- Mechanical Engineering: Precision design & complex assemblies

- Electronics & Embedded Systems: PCB & component integration

- Systems Engineering: Merging mechanical, electronic & software layers

VISION STATEMENT

“Lab9 is creating India’s next industrial revolution — where additive manufacturing, mechanical design, and electronic systems converge into one ecosystem.”

THE VISION

Lab9 was founded to bring together precision design, advanced materials, and modern manufacturing intelligence under one roof.

It’s a living system — not a static workshop — where innovation cycles from idea → design → print → validation → production at remarkable speed.

The goal is simple but radical:

To make India’s next generation of high-performance, intelligent machines —

starting from sand, metal, and motion.

Frequently Asked Questions

Lab9 removes the friction between digital design and physical manufacturing by eliminating:

- Tooling and pattern lead times

- Design compromises caused by mold constraints

- Iteration delays between design and testing

- High costs for low-volume manufacturing

This allows CAD data to move directly into functional parts, molds, and tooling without traditional manufacturing bottlenecks.

Lab9 serves a wide range of engineering-driven users:

- Makers and hardware startups

- Mechanical and product design engineers

- Foundries and industrial OEMs

- Maintenance and operations teams

If manufacturing is slow, expensive, or limits your design freedom, Lab9 is designed for you.

Lab9 does not treat 3D printing as an isolated process. Every project is evaluated for:

- Functional and load-bearing requirements

- Material behavior and durability

- Post-processing and machining interfaces

- Assembly and lifecycle cost considerations

The result is a component engineered for real-world use, not just a printed object.

Lab9 supports both prototyping and production use cases, including:

- Bridge manufacturing and short-run production

- Production-grade sand casting molds and cores

- Repeatable jigs, fixtures, and gauges

- Functional end-use components

The deciding factor is cost per function delivered — not volume alone.

Lab9 aligns with the future direction of manufacturing, including:

- Distributed and localized production

- Digital inventory replacing physical storage

- Tooling-light and iteration-friendly workflows

- Faster engineering and innovation cycles

Lab9 removes unnecessary inertia from manufacturing while preserving engineering discipline.